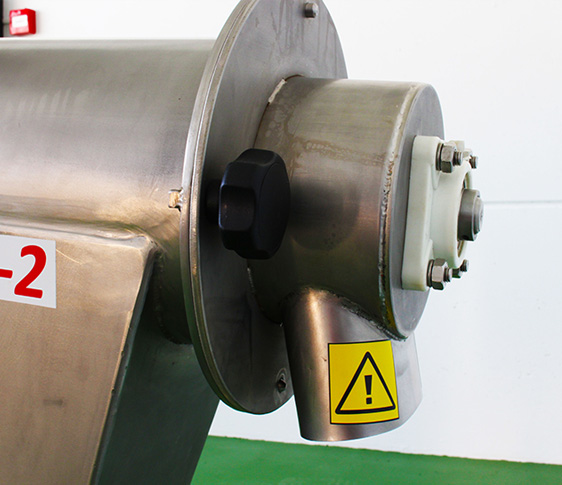

DE-STONING FRUIT AND VEGETABLE

Industrial machines for the processing, pulping and pitting of a wide range of fruits and vegetables. Designed for a high production of fruit and vegetable pulp extraction, managing to separate fresh fruit pulp from waste such as seeds, stones, skin, peels and leaves with an extraordinary performance guaranteed, as little waste is produced. Interchangeable sieves with different perforation sizes depending on the type of fruit to be processed.